THE WHAT, HOW, AND WHY OF RECYCLING POLYETHYLENE

THE WHAT, HOW, AND WHY OF RECYCLING POLYETHYLENE

Polyethylene products like HDPE and LDPE are made from petroleum. Left on their own, they take over 400 years to decompose. However, both of these products are easily recyclable and can have a big impact on the world around us.

What is Polyethylene?

Polyethylene is a plastic. There are two main types: HDPE and LDPE. HDPE stands for high-density polyethylene, while LDPE is low-density polyethylene. The difference between the products comes down to their molecular structure.

HDPE is a linear polymer. This means that the molecules line up instead of branching out. Because the molecules fit so closely together, it has a slightly higher density than LDPE. Having a higher density means it's stiffer and opaque. Hard plastic products like milk jugs, shampoo bottles, and some industrial tubing use HDPE to give them their strength and durability.

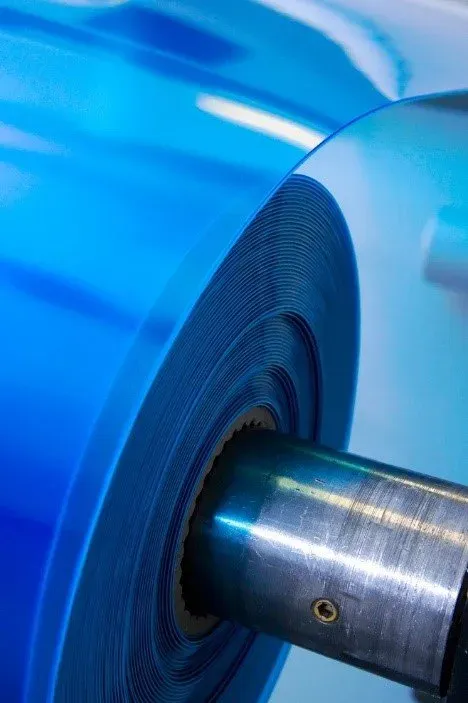

LDPE predates HDPE and has a slightly different structure. Instead of being linear, its molecules occasionally branch out, looking like microscopic trees. This extra space makes it less dense. A lower density means it is more flexible and typically translucent. Sandwich bags, garbage bags, and trashcan liners are made of LDPE.

How is Polyethylene Recycled?

Every plastic has a different recycling process, so when plastics come to the recycling center, they are separated into different types. A sink-float test separates HDPE from PET, which differs greatly in density. HDPE is less dense, and floats to the surface, while PET gathers at the bottom of the tank.

Other plastics are more difficult to separate. Other methods, like Near-Infrared Radiation help sort different plastics so they can be recycled individually.

Once separated, each plastic is shredded and melted to make it more homogenous. This new, recycled plastic is broken into pellets for future use.

Why is Polyethylene Recycled?

Unrecycled polyethylene fills up landfills or becomes waste that hurts the environment for centuries. However, recycling these plastics not only negates these adverse effects but has a positive effect on both the environment and the economy.

Recycling polyethylene is cheap. It's cheaper than incineration, cheaper to use in manufacturing products, and cheaper than disposing of in a landfill. Recycled polyethylene can find a new home in toys, recycling bins, and envelopes.

As you can assume, recycling this plastic has a positive effect on the environment. Polyethylene is made in part by fossil fuels, and 1.75 kg of oil produces 1 kg of HDPE, so by reducing plastic production by recycling, we can lower our use of fossil fuels and decrease our carbon footprint.

However, even though polyethylene is among the easiest plastics to recycle, a lot of it ends up as waste. In 2016, only 14 percent of plastic waste was recycled around the globe. While most steel cans end up at a recycling center, the vast majority of recyclable plastics end up buried or incinerated.

Conclusion

Polyethylene is a common and useful plastic used worldwide. Billions of tons are manufactured every year, and most of it ends up in a landfill. However, there is a better option. Recycling HDPE and LDPE is good for the economy and the environment. What's more, these plastics can be recycled up to 10 times.

Recycling laws are different by state, so be sure to look up the best way to recycle your plastics. A simple drive to a recycling center may not seem like much, but the earth will thank you for it.

At Seiler Plastics, we make customized, plastic extrusions that can satisfy the most challenging of designs. With over 40 years of experience, we know how to get you the tubing, sheets, and thermoformed products you need. These products are durable enough to last for centuries, so make sure to recycle when you're done with them.