WHAT ARE THE ADVANTAGES OF POLYETHYLENE PLASTIC TUBING?

WHAT ARE THE ADVANTAGES OF POLYETHYLENE PLASTIC TUBING?

If you need to manufacture plastic tubes, polyethylene is a good option. This polymer comes in a range of compounds, all of which share some common advantages on top of their individual benefits.

What are the benefits of using polyethylene to manufacture your tubes?

Flexible Applications

Polyethylene is a versatile material. You can use it to make tubes for many different applications and purposes.

For example, polyethylene can safely carry many liquids, gases, acids, alcohols, and chemicals. It creates robust protective tubing sleeves and has good electrical insulating properties.

This polymer is also a non-toxic material that has FDA approval for use on food and beverage products. It doesn't add taste or odor to anything it contains, carries, or touches. It doesn't absorb substances into its structure.

You can also color polyethylene tubes to your specification. For example, you can use this material to create multi-colored drinking straws. Or you can color-code tubes in an industrial environment to make it immediately obvious which liquid or material a tube holds or carries.

Lightweight Flexibility

Tubes made from other materials, such as metals or more rigid plastics, are often heavy. If weight is an issue for you, then using polyethylene tubing is a good alternative. Even if you use a heavy-duty compound like high-density polyethylene, your tubes will still be relatively lightweight.

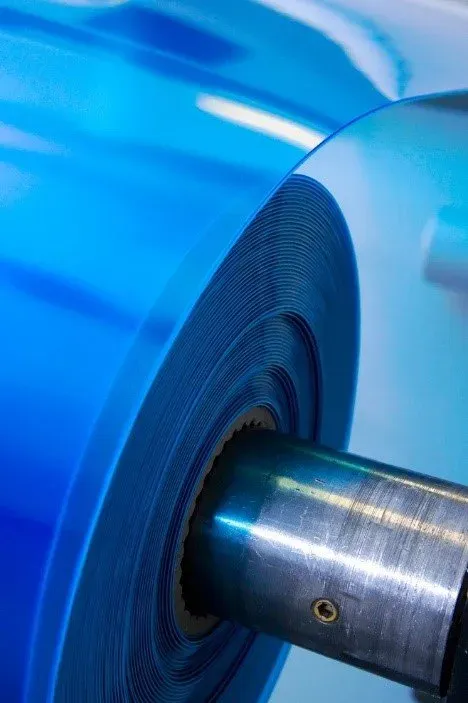

Polyethylene tubes also have some built-in flexibility that you might find useful. These tubes can bend and flex to a certain degree. This makes them easier to use in tight spaces and awkward angles. If the tube needs to move during installation or when it is used in a product, then it can do this. If you're buying long lengths of tubing, you can store them easily on reels or spools.

Good Tensile Strength

The fact that polyethylene tubes are lightweight and flexible doesn't mean that they lack strength. Even low-density polymers are impressively robust. If you up the ante and choose a high-density option, then you get even stronger tubes.

Polyethylene has good tensile strength. Tubes made from these compounds can withstand cracking, impacts, stress, and damage without breaking. They also won't suffer from abrasion wear or fatigue as much as some other materials.

A lot of this is down to polyethylene's high levels of ductility. If a material is ductile, then it has the capacity to stretch or flex when it is put under pressure. Rather than simply breaking when the pressure is too great, a ductile material can take more strain. It will break or fracture much less easily than a more inflexible material.

Polyethylene tubes also have good resistance against corrosion. Like any other plastic, they can't rust. They also won't be affected by corrosive materials such as acids in soil. They won't rot or break down if they come into contact with mold, bacteria, or other growths.

This extra resistance adds to the strength of the polymer. So tubes made from this material typically last longer and perform better.

Keep in mind that polyethylene compounds all do slightly different jobs; they have different strengths and weaknesses. This can affect the type of polyethylene you need to make your tubes.

For example, the rigidity of your tubes will vary depending on the compound you choose. If you want more rigid tubes, then you need a high-density polyethylene. Or if you want more flexibility, a low-density material is likely to be a better option.

If you think that polyethylene looks like being a good option for your tubing order, then contact Seiler Plastics. We can discuss your needs and help you choose the material that delivers the right solution. We can also help you design and produce custom tubing solutions if you need them.